TOP SALES

TOP.01

Rotary weighing filling and capping integrated machine

Mainly for quantitative filling of edible oil, lubricating oil and other oil products. Each filling pipeline is metered by a flowmeter, and the flow metered by the flowmeter is reflected to the comp

TOP.02

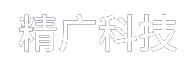

Linear weighing filling machine

Before filling, the upper weighing filling machine counts and judges whether there are all bottles at each filling station by the sensor on the conveyor belt. If the conditions are met, the filling

TOP.03

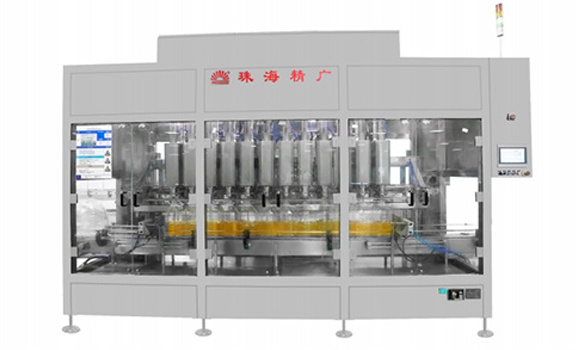

Medium packaging rotary weighing filling machine

The full-automatic rotary weighing filling machine for medium packaging is mainly used for filling large capacity liquid grease (10L-20L). Compared with other filling equipment, the rotary weighing fi

TOP.04

Flowmeter filling machine

High Quality 80gsm Premium Top Coated Self Adhesive Direct Thermal Label Material in Jumbo Roll Sticker Label

TOP.05

Servo piston filling machine

Compared with weighing and flowmeter filling machines, servo piston filling machines are more suitable for filling small packages of edible oil, and the error can be controlled within 1g.

TOP.06

Shuttle type stereo warehouse

It can realize the automatic handling, storage, inventory, warehouse management and other functions of the whole pallet goods in the intensive storage stereoscopic warehouse, and meet the requiremen

Visual inspection is mainly used for automatic production line equipment, the use of visual inspection products on the target to capture the image information, industrial computer after processing,

View More +Flexible conveying system is usually composed of flexible chain plate, driving wheel, passive wheel, aluminum alloy bracket, aluminum alloy guide rail, lining strip and guardrail. It has the advanta

View More +Stainless steel chain plate conveyor line is a common equipment in automatic packaging production line. Because the running part of its bearing part is made of metal, compared with other continuous

View More +Bottle clamping conveyor, also known as automatic vertical bottle conveying machine, lifts or lowers empty bottles between floors, and can directly connect the inlet and outlet of bottle conveying m

View More +Stainless steel roller conveyor is a kind of conveying equipment with powered roller and animal material transmission. It has simple structure and good bearing capacity. The power of the motor is tr

View More +Stacking robot is a high-tech product integrating machine and electricity. It automatically stacks the bags, cartons or other packaging materials transported from the conveyor according to the worki

View More +WHO WE ARE

ABOUT US

Zhuhai Jingguang Technology Co., Ltd. is a professional manufacturer of intelligent packaging machinery and equipment, the products include bottle blowing machine, filling machine, labeling machine, unpacking machine, packing machine, sealing machine, palletizing machine and intelligent stereo library, etc....

RICH EXPERIENCE

ADVANTAGE

Our factory is equipped with international advanced machines and the morden management system. The strict inspection system runs through every step of our manufacturing process: purchasing the material, producing the goods, packaging them, and delivering them. We always aim to provide our clients with the most realiable quality and thoughtful service. We insist: “Integrity Based, Technology Leading, Quality First and Service Foremost ”; We own the professional technology and a most pertect team;We grow up with all customers both home and abroad.

Here breeds unlimited vitality; here coheres a power of wisdom. We, ShuangEn, are fully prepared to meet the challenges with a brand-new outlook towards the world.

WHY CHOOSE US

The company has 100+ workers

The company was established in 2009

Automatic production lines

The factory covers an area of 4,000 square meters

NEWS

What factors affect the filling speed of edible oil filling machines

The filling speed of edible oil filling machines is influenced by various factors such as equipment design and configuration, technical performance and parameters, production environment and conditions, as well as operation and maintenance

Is it necessary to equip the edible oil filling production line with digital twin technology

For edible oil filling production lines, it is necessary to equip them with digital twin technology. However, companies need to adapt to their actual situation and development needs

New Era of Edible Oil Filling: Fully Automated Production Line Solution

In today's rapidly developing food industry, edible oil, as an indispensable basic ingredient for home cooking, has a direct impact on consumers' health in terms of production quality and efficiency

Why are water filling machines not suitable for filling edible oil

Due to the difference in physical properties between edible oil and water, the filling machine for water filling may not work properly or achieve the expected filling effect when filling edible oil